News

18 April 2024TKI Project: Reducing water consumption in mining

The growing global population, shift to renewable energy sources, and the increase in electric transportation are leading to a rising global demand for base metals such as copper, lithium, and nickel. These metals used in batteries are crucial for the energy transition. Miners are investing more and more to meet the rising demand and are continuously striving to reduce the often adverse environmental effects of their operations. One of these effects is water consumption.

Royal IHC and NWP member Deltares have developed a system called ARM (Autonomous RheoMeter), which measures waste production during mining operations. This system is unique because it can measure the density and rheology of different types of waste slurries. ARM helps optimise thickening processes in mines, allowing up to 15 percent of the daily process water to be recycled. The new ARM system could lead to significant water savings in mining processes and help in faster waste disposal and recovery, which will reduce pressure on local water resources and reduce conflicts. Watch the explanatory video about the Autonomous RheoMeter.

Tailings thickeners

Tailings thickeners are used to settle suspended solids and return the water to the process plant. For optimal operation of these tailings thickeners, an automated control system is required to accurately add flocculants. Flocculants are used to enhance the thickening of tailings, thus resulting in increased water recovery. However, controlling these tailings thickeners based on solids or density measurements alone has proven insufficient. The thickened tailings rheology governs the efficiency and quality of thickening, slurry transport, and deposition. In addition, manual measurements of the rheology do not provide enough information for the control system because of their infrequent measurements – usually only once or twice a day.

Real-time data

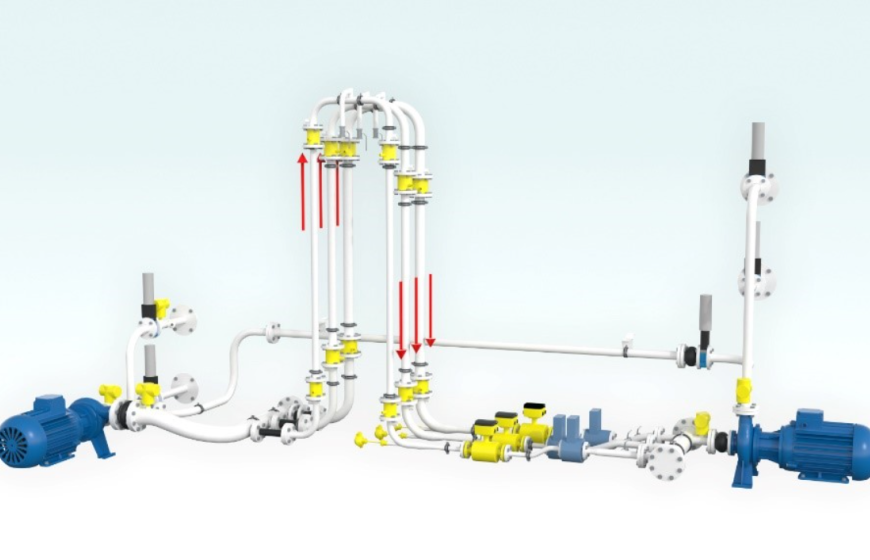

The ARM is a large-scale autonomous rheometer using a side stream of the tailings underflow from the thickener unit. The system enables the plant operator to continuously measure the rheology of the mine tailings. Inside the ARM container are three U-loop pipes between the pumps, with different nominal inner diameters. The sizes are not universal but specific to the tailings and intended application. Each is determined individually according to the expected shear strength and dynamic viscosity of the tailings.

Functioning

The ARM, fitted with two centrifugal pumps, one near the inlet and the other one just before the outlet, forces the tailings through the system and back to the tailings pipe. The system is further fitted with controllable pinch valves and flow sensors downstream of the U-loops for precise control of the flow velocity in the U-loops. These are in addition to having an auxiliary water flush system for cleaning and calibration.

The ARM measures the rheology parameters of non-Newtonian slurries, creating a rheogram every 10 minutes. Unlike other meters, this no longer needs to be done manually, resulting in more and better measurement data, limited maintenance requirements, and real-time data.

Originally, the ARM was designed to measure tailings, but it can be used in any situation where the rheology or viscosity of a slurry during transport is required. This information can be relevant in several cases, such as to optimise the dewatering of tailings, or when the characteristics of a slurry are needed to transport it over long distances.

The ARM is a great example of what happens when industry and research institutes join forces to create an industrial viable solution based on scientific research and combined with high-end instrumentation.

Wiebe Boomsma

R&D Manager Mining at Royal IHC

The TKI Water Technology Programme

The TKI Water Technology Programme shares information about financing opportunities and can connect entrepreneurs and innovators to knowledge institutes and other SMEs. The programme targets companies that offer solutions for specific challenges in the agriculture, food, and horticulture sectors, companies operating in the field of energy, and companies working in the field of clean and healthy water.

TKI Water Technology is part of the Top Sector Water and Maritime (TSWM). The initiative is implemented as part of a collaboration between the Netherlands Water Partnership (NWP) and Water Alliance.

Read more on TKI Water Technology

Featured NWP members: Deltares